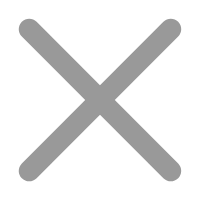

北方伟业计量集团有限公司

-

登录 |

-

官方微信 |

-

在线支付 |

- 网站地图

- 产品

- 帖子

- 新闻

- 课堂

- 文库

北方伟业计量集团有限公司

Normally, the maximum humidity in a pharmaceutical clean room is supposed to lie below 70% to prevent the formation of moulds.

通常,制药洁净室的最大湿度应为70%以下以避免霉菌产生。

In the GMP measuring point list, the humidity sensor is usually defined with an alert limit at 60% and an action limit at 70%.

对于GMP监测点,湿度探头通常设置警戒限为60%,行动限为70%。

A real risk of formation of moulds only exists if elevated humidity values occur over a longer period of time. Different values for this can be found in literature, like more than three hours a day with a surface humidity of 60-100% (in German language), for example.

只有长时间相对湿度较高才有形成霉菌的风险。这可以在文献中找到,如每天超过3小时表面湿度达到60%-100%。

According to DIN report 4108-8 (prevention of mould growth in residential buildings), mould formation occurs if the relative humidity of a surface reaches a value of more than 80% for at least twelve hours a day on at least five consecutive days.

根据DIN报告4108-8(住房预防霉菌生长),如果表面的相对湿度每天至少有12小时超过80%并持续5天,将会生长霉菌。

登录后才可以评论

立即登录通话对您免费,请放心接听

温馨提示:

1.手机直接输入,座机前请加区号 如13803766220,010-58103678

2.我们将根据您提供的电话号码,立即回电,请注意接听

3.因为您是被叫方,通话对您免费,请放心接听